Questions & answers

As the VVR changes the way that some hydraulic systems are conceived, we sometimes face resistance and get repeat questions from interested parties. You can find the most common of these and their answers below.

Will the system over heat?

See Fluid cooling to know more.

Can the VVR handle large flows?

Yes! The VVR is not affected by flow since the returning line does not pass through the VVR (See Installation tip & Circuit layouts). This following video is showing a test-stand demonstration using a VVR400 with a Hagglund’s MB283 radial piston motor (18,000cc /rev. - 1100 in³ /rev.) in a closed loop circuit that ran for many weeks at 150l/min (40 GPM). Such a unit would typically require a ≥250l classic reservoir.

Due to the small volume of oil, will the system quickly stop in the event of a leak?

Yes and this is a great feature to avoid serious environmental damage. If you have an issue with a hose or any important leakage, you will have to stop at some point anyway. With its 6.6 or 14 liters, the VVR will inform you sooner that you have a problem than a 250-liter conventional reservoir would do. A contactless switch is installed on top of the VVR, thus it can be used to send a signal to an alarm or engine kill-switch if the oil level runs low to avoid any damage to your system. Filling the VVR is very simple and fast, taking 20-25 minutes at most (see Fill procedure). Filling up 150-200+ liters may require more complex logistics.

Can the VVR be used on numerous pumps at the same time?

Yes, you simply have to build a distribution manifold or design a simple split valve system according to the number of pumps you have. Every VVR comes with 2 SAE-16 ports that can be used / shared for pumps.

Can the bellow resist high pressure?

Yes, the below is designed to withstand pressures of up to 300 psi but the VVR operates at a pressure or 9 psi of less. The pressure in the return line is modest. The VVR can be fitted with an overboard relief valve that will open at 15 psi in the event of a malfunction in the system. This works as a fuse and protects other components in the network.

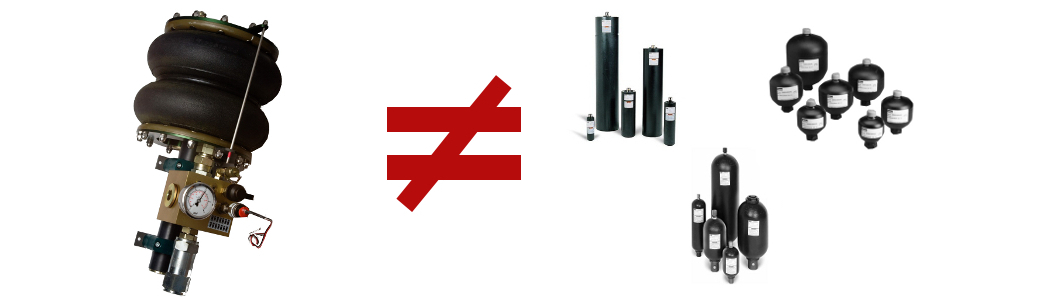

Could the VVR be simply replaced by accumulators?

No, the table below compares the VVR to 3 common types of accumulators.

| VVR | Accumulator |

|---|---|

| The VVR reacts to fractional pressure variations | The piston accumulator does not react to small pressure variations |

| Temperature variation does not affect the VVR performance | Temperature variations have a direct effect on gas pre-charge pressure thus affecting output characteristics |

| Total weight: 36 pounds for 7 liter model | Varies, but likely much heavier and bulkier than the VVR |

| Not affected by altitude or environmental pressure changes | Not affected by altitude or environmental pressure changes |

| No leak No gas required |

Gas leak hazard Gas pre-charge required |

| Total volume: 7 liters / 400 cubic inch | Oil volume: 7 liters + gas volume: 20-25 liters |

| Linear output | Subject to gas law Isothermal or adiabatic state |